uorescent ink production process for printing anti-counterfeiting labels on products

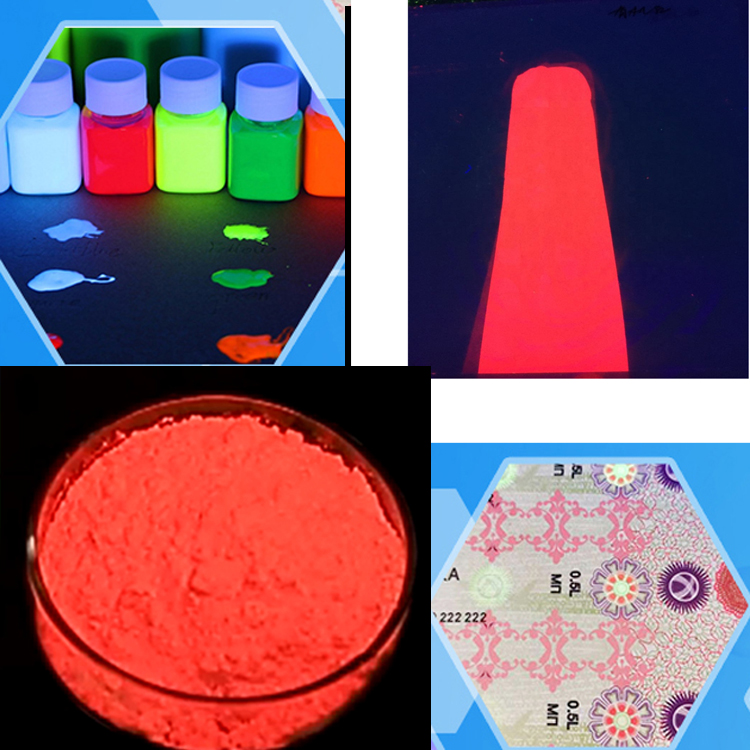

Introduction: This technology relates to a fluorescent ink used for printing anti-counterfeiting labels on products, including organic ultraviolet fluorescent powder: 12-16 parts; Connecting materials: 38-42 portions; Light stabilizer: 7-11 parts; Water reducing agent: 4-8 parts; Defoamer: 1-5 parts; Deionized water: 43-47 parts. This technology uses water as a solvent to prepare water-based fluorescent ink. The process is simple, and there is no wastewater generated throughout the process. The production cost is low, and it is green and environmentally friendly; The fluorescent ink prepared simultaneously has good fluidity, light resistance, thermal stability, water resistance, and adhesion; At the same time, it improves the stability of fluorescent ink, and its long-term storage will not cause sedimentation, thereby extending its shelf life; In addition, the use of water reducing agents reduces the amount of deionized water used, which is about 26% lower than traditional processes, thereby reducing resource waste and energy conservation and environmental protection.

Post time: Jun-24-2024