A. The fluorescent color is bright and has good covering power (without the need for opaque agents).

B. The particles are fine and spherical, easily dispersed, with a diameter of about 1-10u for 98%.

C. Good heat resistance: The maximum withstand temperature is 600amp # 176C, suitable for various high-temperature processing. Good solvent resistance, acid resistance, alkali resistance, and high stability.

D. No color shift, no pollution.

E. Non toxic, does not spill formalin when heated, can be used for coloring toys and food containers.

F. The color body will not overflow, which can save cleaning procedures when changing the mold inside the injection machine.

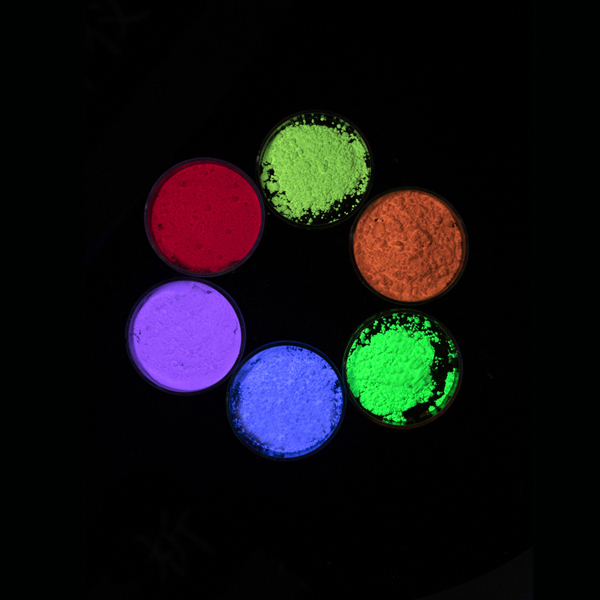

Organic fluorescent powder:

A. The fluorescent color is bright and lacks covering power, with a light penetration rate of over 90%. Good solubility, all kinds of oily solvents can dissolve, but the solubility is different, so it needs to be selected according to different needs when using.

B. Belonging to the dye series, attention should be paid to color shift issues.

D. Due to poor weather resistance, other stabilizers need to be added during use.

E Heat resistance: The maximum withstand temperature is 200amp # 176C, suitable for high-temperature processing within 200amp # 176C

Application Area

1. Can be used for drawing in entertainment venues, drawing under UV lighting. 2. Produce anti-counterfeiting ink, anti-counterfeiting paint, and anti-counterfeiting coatings

3. Conduct product quality testing

4. Long wave fluorescence anti-counterfeiting technology is an advanced anti-counterfeiting technology currently used in bills and currencies, with good concealment and relatively popular identification instruments (money detectors are often used in shopping malls and banks for identification). Short wave anti-counterfeiting technology uses specialized instruments for identification, thus having stronger anti-counterfeiting and concealment performance. Fluorescent invisible ultraviolet excitation phosphor. This phosphor exhibits dazzling fluorescence under ultraviolet irradiation and is widely used for anti-counterfeiting. It has the characteristics of high technological content and good color concealment.

Post time: Jun-26-2024